Pressure vessels are industrial containers designed to hold vapors, liquids or gases.

Because pressure vessels usually hold materials at a high pressure they can be dangerous if not properly maintained. Regular inspections are a critical part of the maintenance process for pressure vessels, helping to reveal potential problems before they develop further.

Because pressure vessels usually hold materials at a high pressure they can be dangerous if not properly maintained. Regular inspections are a critical part of the maintenance process for pressure vessels, helping to reveal potential problems before they develop further.

Here is a list of the topics covered in this resource to help you find the information of most interest to you:

Although we have already provided a definition of pressure vessels in the first sentence of this article—they’re “containers designed to hold vapors, liquids, or gases at a specific pressure”—each country has strict definitions of what they are, so it’s worth spending some more time defining them.

The reason for these narrow definitions is because pressure vessels are dangerous.

To help mitigate the dangers they pose, almost every country in the world has laws regarding how pressure vessels are designed, how they’re built, and how they can be operated.

In addition to general regulatory requirements for pressure vessels, every individual pressure vessel has specific operating limitations, called its “design pressure and design temperature.”

If a pressure vessel is operated beyond the pressure or temperature it was designed to handle, the result could be the catastrophic failure of the unit. In the worst case scenario, operating outside of a vessel’s design could lead to fires, poisonous gas leaks, or even explosions, all of which could pose an extreme danger to anyone working in the surrounding area.

Common Characteristics of Pressure Vessels

Note: Psig is a measure of pressure that stands for Pounds Per Square Inch Gauge. Learn more about psig on the Energy Education website.

Types of Pressure VesselIt’s important to note that the term “pressure vessel” can refer to a variety of

storage containers used in industrial settings.

Here are some of the most common types of pressure vessels.

Inspections are a crucial part of the maintenance process for pressure vessels.

This section covers information on the frequency with which inspections should

happen, what is done during inspections, the types of testing that can be used in

inspections, and ends with a checklist of what is generally covered during a

pressure vessel inspection.

Most pressure vessel regulations provide specific requirements for the frequency of inspections. As a general rule of thumb, pressure vessels should be inspected at least once every five years. An inspection should also be conducted once the vessel is installed, prior to it being put into service.

What is done during and Inspection

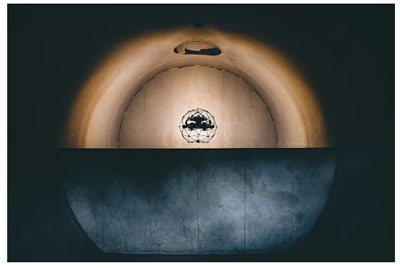

Pressure vessel inspections can refer to an inspection of the vessel’s condition

externally, internally, or both.

In these inspections, inspectors may :

Types of Pressure Vessel Testing

There are five common types of tests inspectors perform during pressure vessel

inspections :

1. VISUAL TESTING

Visual testing is the most common type of non-destructive testing (NDT) an

inspector might perform. The goal of a visual inspection is to visually review both

the interior and exterior of the vessel to look for any cracks or flaws (see the

checklist just below for more details). Learn more about visual inspections.

2. ULTRASONIC TESTING

Ultrasonic testing uses sound waves to measure the thickness of a material’s

surface in order to detect any defects that may have arisen. This kind of testing is

volumetric, meaning it can detect flaws inside the vessel as well as on its

surface. Learn more about ultrasonic testing.

3. RADIOGRAPHIC TESTING

Radiographic testing uses radiography to detect defects near the surface or on the

surface of a vessel. This testing method is also volumetric. Learn more about

radiographic testing.

4. MAGNETIC PARTICLE TESTING

Magnetic particle testing uses magnetic current run through the pressure vessel to

identify deformations or defects on the surface of the vessel, which will interrupt

the flow of the magnetic current and appear as a “flux leakage field.” Learn more

about magnetic particle testing.

5. DYE PENETRANT TESTING

Dye or liquid penetrant testing uses liquid (i.e., the penetrant) sprayed onto the

vessel to identify defects or flaws on its surface. A fluorescent chemical can be

added to the penetrant to make flaws visible under U.V. light. Learn more about

dye penetrant testing.

Pressure Vessel Inspection Checklist

Here is a checklist of the things inspectors usually look for during a pressure vessel

inspection.

EXTERNAL INSPECTIONS — WHAT TO INSPECT

Here's what inspectors look for when inspecting the exterior of a pressure vessel:

INTERNAL INSPECTIONS — WHAT TO INSPECT

Here's what inspectors look for when inspecting the interior of a pressure vessel